Linking Business Transformation and Continuous Improvement to Optimize your Enterprise

Workplace Organization

Using data collection and digital tools we map and visualize the structure of your process and identify opportunities for improvement. From there we create an organizational strategy designed to get the most out of your space, time, and resources. By establishing best practices, we eliminate redundancy, waste, and inefficiency to create consistent and sustainable processes that turn short term improvement into long term growth.

Kaizen

Visual Workplace

Standardized Operations

Companies where we have implemented operational excellence

Time Reduction

We eliminate unnecessary tasks and steps in the process flow so you get the most out of your time. Flowing it right means creating processes that are lean, focused, and easy to implement in order to increase productivity and ensure each of your customers gets what they want, when they want it.

Creative Problem Solving

Approach a problem in an imaginative, innovative, and unconventional way.

Project Management

Lead and train a team to hit goals and complete deliverables within a set timeframe.

Process Improvement

Analyze and improve existing business processes to optimize performance, meet best practice standards.

Have any questions?

Reduction

Let us do a quick inspection of your operation and we will give you an estimate of how we can help you.

Call us today

Applied Business Management

Through analysis and consultation, we map the road from aspiration to reality through a series of practical and attainable steps catered to the specific strengths and needs of your business. We then craft communications strategies so that every level of your organization understands your vision and their responsibilities in realizing it. Our approach is not just a change in tasks and processes but in how employees think about and view their role in the business.

Optimization for maximum productivity

Supply Chain Architecture

Using both direct and data driven methods of examination we analyze your network and identify opportunities to reduce waste. Our next step is to organize your supply chain and inventory to eliminate redundant and inefficient expenditures to ensure timely, easy, and consistent access to necessary resources throughout your process. Through standardization and leadership training we establish a continuous and sustainable flow that allows you to deliver a dependable product even in the face of changing markets.

Supply Chain Design

• Production Planning and Inventory Control

• Pull System

• Heijunka

• Total Productive Maintenance

Supply Chain Flow

• Information Flow

• Product Flow

• Logistic Flow

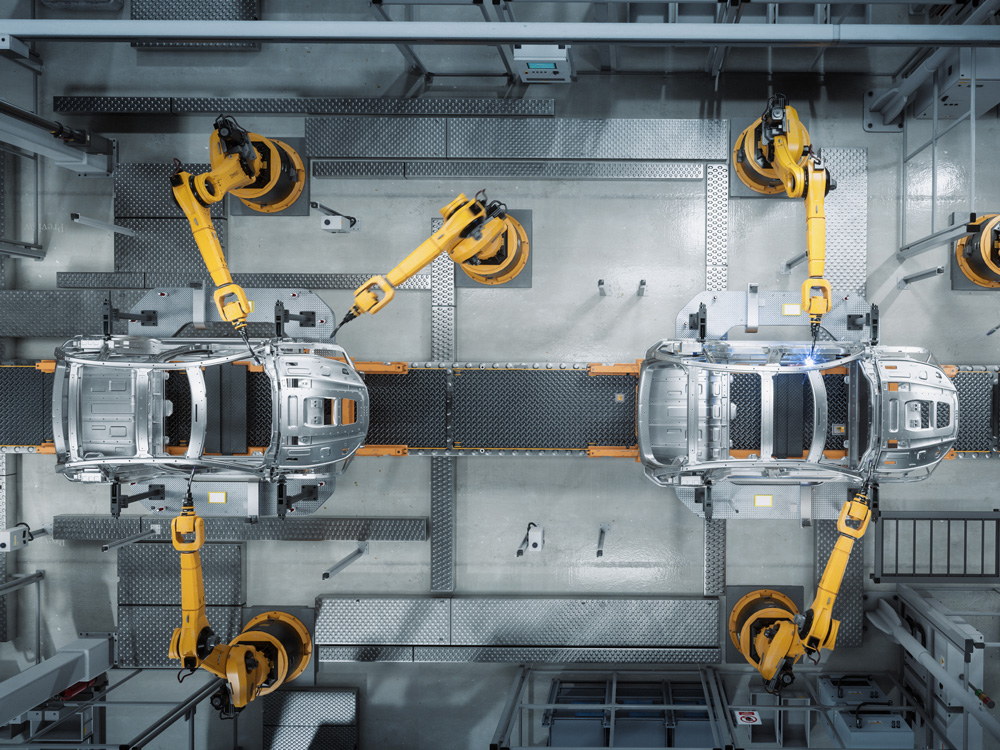

Examples of industries we work with

Transportation

and Logistics

Warehousing

Restaurants and

Grocery

Goods Producing

Manufacturing

Healthcare and

Social Assistance